Commercialization of Calcium Carbide and Acetylene

Calcium carbide and acetylene manufacturing process

WhatsApp)

WhatsApp)

Calcium carbide and acetylene manufacturing process

Problems of calcium carbide manufacturing process. Calcium carbide plant causes to environmental pollution. Corol and limestone are used to take CaO. This causes to coastal erosion. Energy required for preparing CaC 2 is higher than getting energy by the combustion of C 2 H 2. Generated heat causes to increase the temperature of environment.

India''s Leading Acetylene Carbide Manufacture. For over a century, the chemical energy delivered by calcium carbide has powered industrial innovation, making it a vital raw material for a diverse range of basic industry needs. Calcium Carbide is the premier slagconditioning and desulfurizing agent for iron and steel; carbide produces acetylene gas

Calcium Carbide Manufacturing General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100#176;C (3632 to 3812#176;F) in an electric arc furnace. At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3CCaC2 +CO

Project Report on Pvc Resin From Calcium Carbide Project Report on Pvc Resin From Calcium Carbide includes Present Market Position and Expected Future Demand, Technology, Manufacturing Process, Investment Opportunity, Plant Economics and Project Financials. Report provides a comprehensive analysis from industry covering detailed reporting and evaluates the position of the

About product and suppliers: 77 iso calcium carbide plant products are offered for sale by suppliers on A wide variety of iso calcium carbide plant options are available to you, There are 5 suppliers who sells iso calcium carbide plant on, mainly located in Asia.

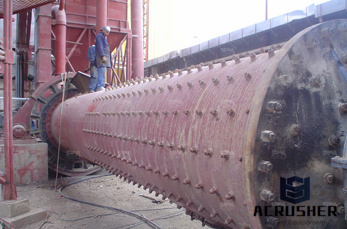

Calcium Carbide Manufacturing Plant The essential equipments for the calcium carbide manufacturing industry are available with many different types. such as refractorybrick and carbon lined arc furnace, electrode hoisting system, control panel, a watercooling tower, jaw crusher, screening plant, conveying system, processing plant etc.

The Leader in Calcium Carbide in Malaysia. We operate a fully integrated plant manufacturing carbide, calcium, acetylene, quicklime, hydrated and putty lime.

CALCIUM CARBIDE USES AND APPLICATIONS The chief applications of calcium carbide are in the manufacture of calcium cyanamide, acetylene required in oxyacetylene welding, synthesis of solvents and organic compounds required in the pharmaceutical and dyestuff industries and manufacture of synthetic rubber and plastics. It is also used in signal fires.

calcium carbide manufacturing process. Calcium carbide manufacturing process calcium carbide is made by heating calcium carbonate and subsequently reducing cao with carbon petrol coke, according to the follow reaction caco cao co cao c cac co co o co the process for manufacturing calcium carbide is illustrated in fig is converted to

The Company''s calcium carbide and lime manufacturing activities were carried out since 1972. MCB Industries Sdn. Bhd. operates a fully integrated plant which uses the most modern technology and the plant comprises of two Calcium Carbide Furnaces with a total capacity

18/3/2015#0183;#32;In 1941, the government contracted with National Carbide to construct a calcium carbide/acetylene gas plant. Several other companies, including Goodrich, located rubber faciliies there, and by 1945 a consortium of five tire companies known as National Synthetic Rubber had opened a plant to support the war effort.

WhatsApp)

WhatsApp)