How a Mill Works: Hard Rock Mining Tour YouTube

Describes how a mill works. Footage from Grinding For Gold: The Mayflower Mill Story DVD and courtesy of the San Juan County Historical Society.

WhatsApp)

WhatsApp)

Describes how a mill works. Footage from Grinding For Gold: The Mayflower Mill Story DVD and courtesy of the San Juan County Historical Society.

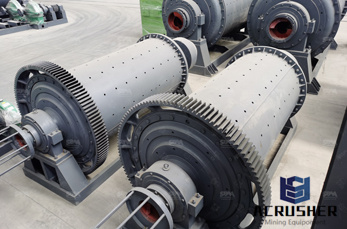

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. T

Mill Operators Conference. About the conference. Embracing the opportunity to provide worldleading professional development and networking opportunities to the global resources community, we are excited to announce the Mill Operators Conference will be delivered in a hybrid event will now be able to attend in person or access the conference content wherever they are in the world.

The occupational endorsement in mining mill operations provides education and training in the skills and knowledge required of a mining mill operator. This program is open to those who have a high school diploma or GED. Minimum Requirements for Occupational Endorsement: 17 credits. Course List; Code

Mining Mill Operations Community amp; Technical . Jan 28, 2019 #183; The Mining Mill Operations program prepares you for a career operating mill equipment and systems used in the largescale mining industry. Mill Operators work where the mined ore is crushed, milled and sent through the various systems to extract the minerals and metals. Read

Mining Systems and Equipment: Students will develop skills and knowledge related to hand and power tools used in mill operations; lifting devices; ladders and scaffolds; sump pump operations; service vehicles and equipment, and general mill operations. Mill Operations and Processes: Students will learn processing basics, including, conveying

Courses Mining Mill Operator Training. Mill Operations and Processes Students will learn processing basics, including, conveying, crushing, grinding, classification, gravity separation, dewatering, extraction, physical and chemical processes, hydromet/pyromet, tailings disposition, and sampling and testing.

Vertical Roller Mill Operation Grinder Market. Above all the core of vertical roller mill operation lies in regular inspection and proper use Of course ZENITH can send our mining engineers to help you make a training for workers on proper operation of vertical roller mill Products Products MB5X Grinding Mill. Read More. E Vertical Roller Mill

MINING. Mining operations at Kumtor are carried out using conventional openpit mining methods. The Central deposit is mined in a large open pit where total material mined in 2010 was approximately 116 million tonnes, or 318,000 tonnes per day. The overall waste

Mining amp; Milling Centerra Gold

Humboldt Mill Operations Eagle Mine . Humboldt Mill. Lundin is refurbishing and reusing the Humboldt Mill, a prominent fixture of Michigans mining history since the 1950s.

cement mining mill machine operation and maintenance. Mining, mineral processing and cement making operations face some of the toughest and most remote working conditions on earth with heat, contaminants, vibration, heavy loads and extreme production demands where lost days can be very costly, you need machinery you can trust

The property was sold to Callan Mining Company who began milling gold from the Ropes Gold Mine in 1985. Callan used the pit to dispose of tailings underwater until operations ceased in the early 1990s. The last company to use the Mill was Mineral Processing Corporation, and for over a decade, the Mill sat idle, falling to disrepair.

The Mining Mill Operations program prepares you for a career operating mill equipment and systems used in the largescale mining industry. Mill Operators work where the mined ore is crushed, milled and sent through the various systems to extract the minerals and metals. Earn a mining mill operations occupational endorsement in 15 weeks and be

Running safe, profitable production operations is becoming increasingly challenging. This is especially true in dangerous and remote environments where mining facilities exist. Many mining companies are looking to allow operations, reliability, production planning, and business operations to be located in centralized locations away from the

Mining Mill Operations Maintenance And Planning. Optimizing mining operations TD World. 1 Functional silos in copper mining Breaking down silos is challenging as there are a number of historical and structural reasons that support the status quo, including geographic distribution of the operations, complexity of the planning process, the fractured software marketplace servicing the industry

Search 225 Mill Operator jobs now available on, the world''s largest job site.

operating a vertical mill in gold mining Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc., and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing process.

The occupational endorsement in mining mill operations provides education and training in the skills and knowledge required of a mining mill operator. Minimum Requirements for Mining Mill Operations Occupational Endorsement: 17 credits. Community and Technical College

Residential Mining Mill Operation. Implemented effectively numerous operations have experienced productivity gains from Mine to Mill in the range of 1020 Cone Mills Corporation Wikipedia Cone Mills Corporation was a world leader in textile manufacturing of corduroy flannel denim and other cotton fabrics for most of the 20th century

Ledcor is one of the few companies to offer turnkey solutions to mining companies across North America. We have the resources to prepare mine sites, extract minerals on contract for clients, build complete mill facilities, manage mine operations, and also carry out reclamation activities once mining operations cease.

Efficient operation even at higher mill speeds Operatorfriendly smooth mill operation Significantly improve wear life Can be precisely designed to handle the given capacity Can be easily retrofitted to existing mills. The optimal performance of AG/SAG mills is the key to successful plant operation.

WhatsApp)

WhatsApp)